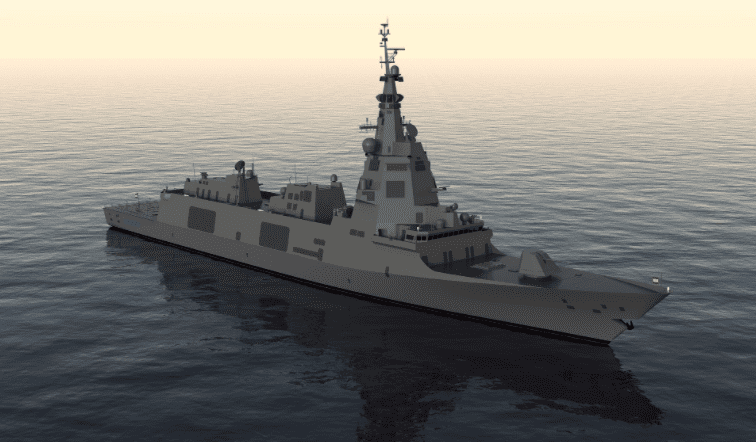

Canadian Surface Combatant Visualization Technology

How Canada got to the point of selecting the BAES Lockheed Martin (LM) Type 26 Frigate as the successful bidder for the RCN’s new Canadian Surface Combatant (CSC) fleet will not be discussed here. What will be discussed is how the ‘paper-ship’ design of the frigate was selected and why the visualization design was so integral to Canada’s decision. Significant investment in computer technology was made to support the detailed design and production of the CSC frigate. Computer-Aided Design (CAD) systems have been in use for many years and Virtual Reality (VR) software is now core to any design process. We will focus on the use of this new technology and the detailed design work. Although the design is now mature, work continues to fine-tune some aspects and support the build phase to adapt the Type 26 for Canadian requirements.

Industries use a system called Visionary Render 2 (VR 2) which takes CAD files and brings them to life in three-dimensional (3D) VR. BAES started using VR 2 for warship design in 2015 and embedded the system into its design. The complex Type 26 Frigate took the potential of VR-assisted design much further, now fully integrated into the design process. The capabilities of VR 2 continue to improve with a program of incremental software updates. The technologies used are not entirely new, but this is the first time immersive VR has been used as a comprehensive design verification tool in warship design worldwide.

In the development of previous generations of warships, plywood mockups were sometimes constructed to help refine the design, test the ergonomics and familiarize crews with compartment layouts. This process was laborious and changes had to be sent back to the designers with new drawings produced. CAD systems started to replace physical drawings in the 1980s and by the 21st century, 3D viewing software linked to CAD systems started to be used. VR 2 technology is now in daily use and fundamental to the development of the Type 26 design.

By using VR 2, it is now possible to ‘walk-around’ the entire virtual ship and examine it in minute detail. Design changes can be quickly made and computer models updated. The ability to perform digital ‘prove-out’ ahead of any commitment to physical building saves time and money. The system also allows compartments to achieve safety sign-off before construction. Features that might present a danger to crews can be evaluated before construction. As an example of the benefits, using CAD data it took two days to analyze the proposed configuration of Heating, Ventilation and Air-Conditioning (HVAC) equipment in one compartment. The same task can now be done in 45 minutes using VR 2.

The complete Type 26 Frigate CAD model runs to many terabytes of data but the VR 2 system is able to use a lightweight version that requires just 3 gigabytes. This allows the system to be run on high-end desktop computers, and an operator can be trained quickly in the basics of using the system. VR has now been taken a step further than just a design tool. Many design/systems engineers are now employed on the UK’s

City-class Type 26 program and VR provides a means for them to collaborate. Design teams can work together in real time with suppliers and manufacturers at dispersed locations to view and develop the design.

After the design sign-off, the VR 2 system then works with the build stage. Data from the design is used to decide quantities and specifications for materials. This improves the ability to generate orders from supplier bases. Once complex and mission-critical parts for the CSC have been constructed, it is now possible, using cameras and laser-measuring tools, to compare the compartment with the original design checking for anomalies and meeting specific tolerances. The computer VR 2 model will be updated with software through the life-span of each CSC and used to de-risk potential upgrades and design changes before they are made. This is especially important as technology and threats are always evolving, which demands flexible ways to accelerate the upgrade process.

The VR computer model of each CSC will continue to support the ship in service as a tool to train crews and rehearse equipment installation or maintenance before the work is done for real. As an example, a VR 2 training tool was developed to help sailors learn their way around the interior of HMS

Queen Elizabeth long before she resembled a complete carrier. In training scenarios, students could select from different paths and click on any part of the ship and see additional information and images in pop-up windows. Canadian customers were shown around the ship virtually before they decided on their specific design. This also helped to deflect some of the criticism that the Type 26 was ‘not mature’ in comparison to other designs that were already at sea.

LM/BAES opened Canada’s first Visualization VR 2 Suite for the CSC in Ottawa in November 2020. This visualization technology will change the way Canadian warships are designed and built in the future. It is possible that the VR-based CSC design/build phase will lead to savings, however, the real benefits of these new techniques are more likely to be seen in the quality of the CSCs, reduced through-life costs and more rapid deployment of new capabilities and upgrades down the road.

To conclude, the CSC Type 26 Frigate is being designed to meet Canada’s needs, and this visualization technology could promote efficiency, quality and safety in the build program. Across the three Type 26 programs in Canada, Australia and the UK, these 3D visualization suites are transforming how future naval ships are designed.

Intelligent search from Bing makes it easier to quickly find what you’re looking for and rewards you.

www.bing.com

www.capebretonpost.com

www.capebretonpost.com